- Home

- Company Tour

- Testing Equipment

To provide customers with reliable and high quality wire and cables, Tong-Da is available in strict quality test in all processes of product production.

Raw material testing

Testers of our quality testing department will conduct strict inspection on the purchased aluminum rods and aluminum clad steel, and after their being tested qualified, issuing quality test record and putting them into warehouse for subsequent use, otherwise, the materials will be labeled as unqualified and be tested again, if still unqualified, they will be send back.

Production process testing

Initial product inspection: When cable production work starts, production of different cables is required or when there is adjustment of production techniques, there will be an inspection work by the operators and after all these processes tested qualified, the testers will complete a record on initial product inspection based on relevant testing procedures, while if initial inspection tested unqualified, there will be a reworking or remanufacturing until they are qualified, then, the products can be produced in large quantities after being confirmed and signed by testers. After the products being completed in each process, they will be inspected in the inspection-waiting area for testing and can be put into next process after being inspected qualified.

Finished products testing

The finished wire and cable products will be tested in appearance by the packaging personnel and will be sent to quality inspection department by special inspectors to have batch sample inspection based on complete and qualified special inspection record.

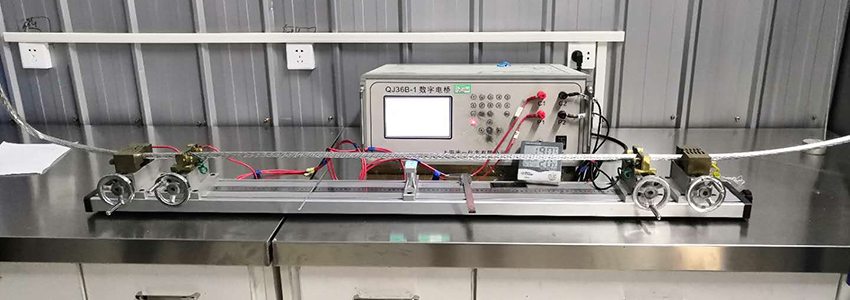

1. Dual-purpose DC bridge for DC resistance measurement

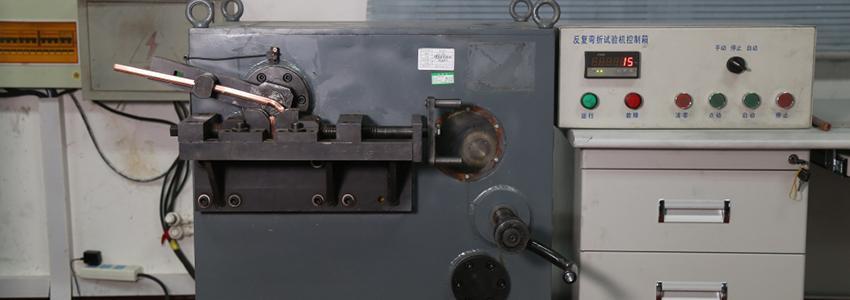

2. Universal electronic tensile testing machine for pulling strength measurement

3. Thermal extension tester for testing performance of wire and cable insulation sleeve and thermal extension of materials

4. Spectrometer for chemical composition of raw material

5. Mechanical Properties (Tensile Strength and Elongation) Tester for cable Insulation and Sheath

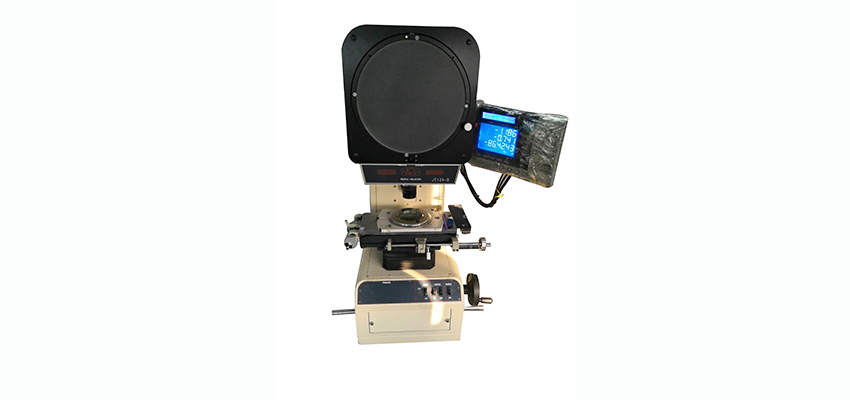

6. Insulation and Sheath Thickness detector

8. Partial Discharge Shielding Experiment to test cable partial discharge and pressure resistant performance

USA - Choose Country

USA - Choose Country